Cutting and Crafting

Sublimation VS Heat Transfer Vinyl: Which is Best?

Both sublimation and heat transfer vinyl are types of printing methods. But each has particular characteristics. That make them useful for some projects and bad for others. Both printing methods involve a similar process, but give different results. For both you need to have an impressive design to create a project, find many at the best prices on bgartdesigner!

What is sublimation?

Sublimation involves printing a design on a special sublimation paper. It works by using a heat press, to transfer the printed design to a polyester fabric or polyester coated surfaces. In this process, the sublimation paper goes from a solid state to a gaseous state. And finally, it becomes a permanent part of the surface when it cools.

What is sublimation heat transfer vinyl?

Sublimation heat transfer vinyl commonly called HTV, is a two-step method. First, print the design on a sheet of vinyl. And then trasnfer it using a heat press. As a result, the design will be an extra layer on the fabric.

Differences between both

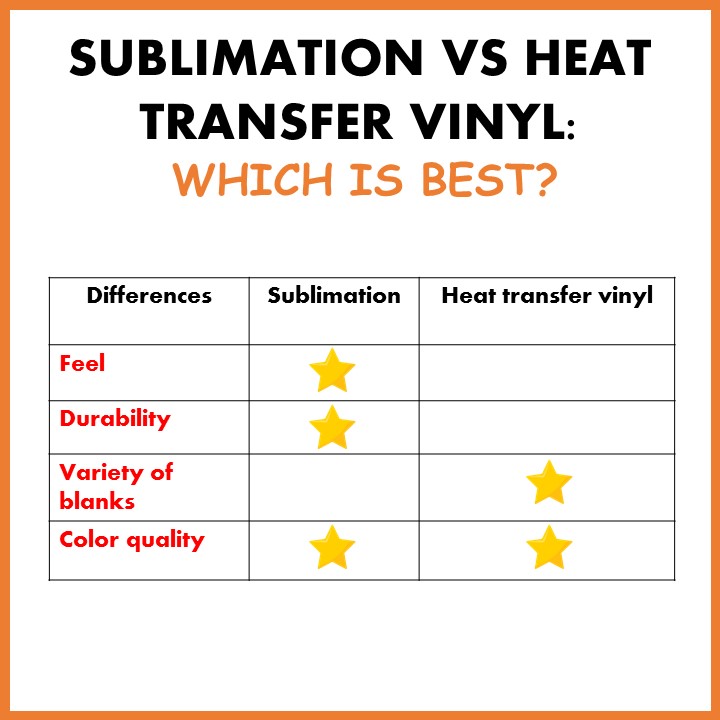

The differences between heat transfer vinyl and sublimation are notable considerations to keep in mind to make the right choice for a business. Here are the differences in various categories!

Feel

Sublimation does not add an extra layer on top of the fabric. This is because the printed and pressed design becomes an actual part of the fabric. As a result, people cannot feel the difference between the printed image and the rest of the fabric.

On the other hand, the sublimation heat transfer vinyl leaves a thin layer to show the design on top of the fabric. So people can tell the difference by feeling the surface.

Durability

In terms of durability, heat transfer vinyl can last 30-40 washes, depending on the size of the design and how it is washed. On the other hand, sublimation leaves a much more permanent design on the fabric and can withstand many more washes.

Also, since sublimation does not leave an extra transfer layer on the fabric, no cracking will occur after washings, and the image is much less likely to fade.

In these categories of durability and feel, sublimation wins, because it can last longer and people don’t feel the actual image transfer on top of the fabric.

Variety of blanks

Sublimation is a much more limited method, this is because it can only adhere to 100% polyester-coated materials for it to work. Even if you use 60% polyester (which is the minimum amount of polyester needed), you are not going to get much vibrancy in the transfer design.

Since sublimation printers do not have white ink, the white parts of the graphic to sublimate will depend on the fabric to fill these spaces. That is the reason why sublimation only works with white or very light-colored fabrics.

On the other hand, sublimation heat transfer vinyl is a unique alternative that allows sublimation beyond white polyester fabrics. This is because all color inks are printed directly onto the blank. In addition, with heat transfer vinyl it is possible to sublimate on cotton or polyester. As well as on ceramic, wood, or metal.

Heat transfer won in this category, because of the variety of surfaces to which it can adhere.

Color quality results

Both sublimation vinyl and heat transfer vinyl allow you to print vivid color images. This can be very useful when trying to sublimate a photo for a particular job that requires a very specific color.

There is a tie in this category because both methods provide a vibrant, full-color design.

Conclusion: Which is best?

The real differences between the two methods lie in durability, feel, and the variety of blanks. The decision of which method to use will depend on the customer’s needs and the type of material required.

If the garments are 100% polyester and white or light-colored, sublimation paper is the best option. As it is specifically designed to reflect the dyes directly onto the substrates. But, if you are working with cotton, wood, or dark-colored materials heat transfer vinyl sublimation is much better; and perhaps the only option.